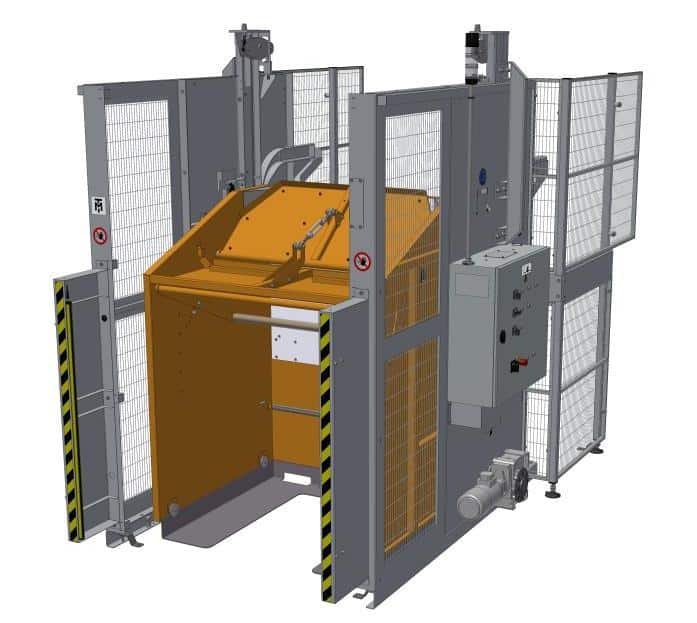

Tanner KPT Tipper Unit

Preform Handling - The solution for preform manufacturers

A tipping device for the customer and the market, which can be adjusted up to customer request.

- Operated friendly

- Long-lasting tipper unit

- Environmentally friendly

- Over 800 Tanner tippers are in use worldwide

Range of different tipping solutions up to customer request.

- Connection possible to any side of the silo rucksack (SRT) or any silo belt (SBT)

- Maximum container size (W x D x H): 1300 x 1300 850-1420mm

- Load possible up to 540kg

- Tipping height: 4m or low ceiling tipper unit 3.7m

Functionality and Design

No hydraulic, the Tanner tipper unit is a clean product based on long-term experience.

Several options possible up to customer request.

- Opening with electrical drive in end position, for preventing the waterfall effect. Smoother loading into the silo.

- Parts made in Inox also available.

- Many more options available and upon request.

In Depth

No hydraulic solution. The mechanical design provides a durable use of the tipping unit. Each component is very resistant to ensure the position in the logistics area.

- Mechanical chain instead of hydraulic

- Several tipper types available

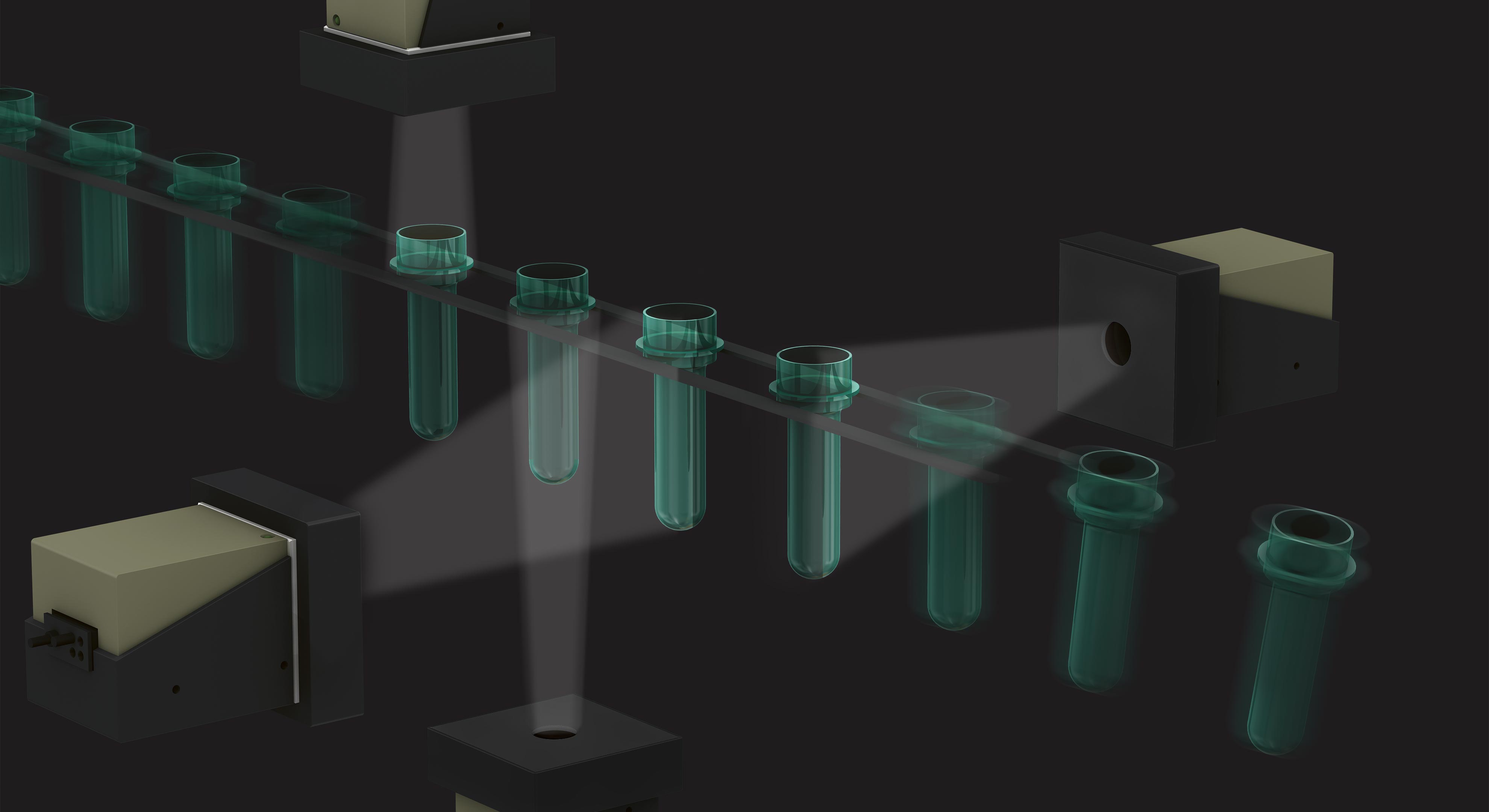

Your Benefits – Swiss Partnership Drives Innovation

Preform inspection meets preform handling on a new market level. It is more than a partnership. Synergies and Swiss quality creates a high standard inspection solution.

- More flexibility

- Market leader in preform handling

- Each company focus on their core competencies

- Think like the customer

- One system from two market leaders in the sector

Preform Inspection

Choose your preform inspection system from different options

Learn more about Preform Inspection