Highlight’s

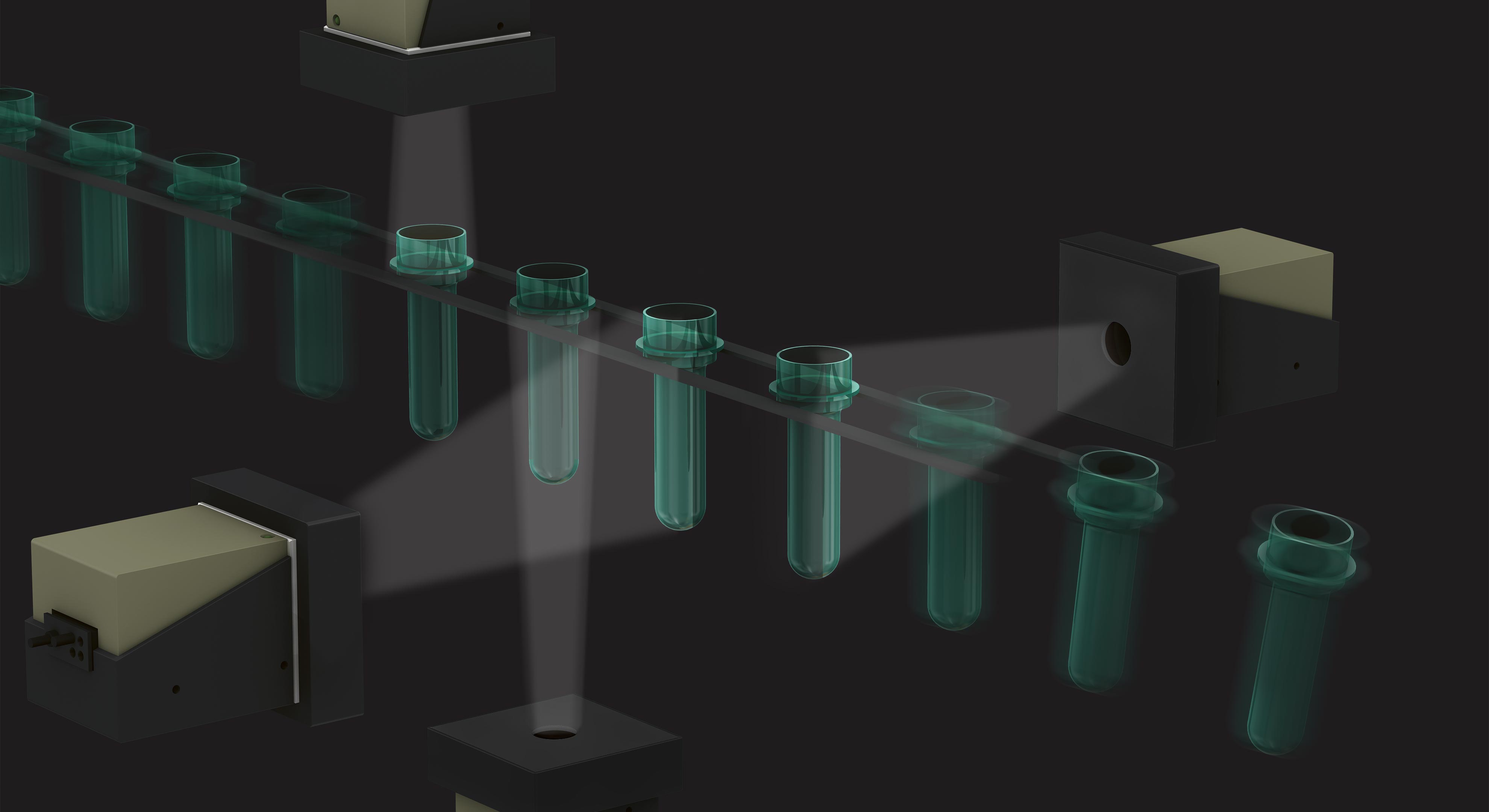

Two in one system. Two z-belts are conveying the bad and good preforms.

After inspection a double z-belt conveyor transports the good preforms into two boxes and the bad preforms into one box. Process optimisation due to three boxes loading after the camera inspection.

Two in one system. Two z-belts are conveying the bad and good preforms.

Flexible positioning – linear, left or right after PECO V3